The New Standard for

Paper Fillers

Revolutionizing Copy, Thermal, and Label Papers with

1:40 CNF Synthesis Technology

1:40

CNF Synthesis Ratio

50%+

Pulp Cost Reduction

Global

Patent Protection

Transforming Paper Manufacturing

FCC Technology delivers breakthrough performance across critical paper applications

Copy Paper

Superior Runnability

Achieve high stiffness and bulk opacity while significantly reducing wood pulp usage.

Thermal Paper

Optimized Base Sheet

Provides a smooth, flawless surface essential for thermal coating efficiency and base sheet strength.

Label Paper

High Tensile Strength

Enhanced durability for die-cutting performance and cost-efficient production.

Why License FCC Technology?

Gain competitive advantage with proven, patented innovation

Cost Leadership

Replace expensive pulp with stable mineral fillers to secure profit margins.

Scientific Validation

Proven technology backed by ACS Sustainable Chemistry & Engineering (2020).

Global Patent Protection

Comprehensive intellectual property coverage across major markets worldwide.

Scalable Production

Industrial-grade synthesis process ready for immediate commercial deployment.

Published Research Excellence

ACS Sustainable Chemistry & Engineering

Peer-reviewed publication validating FCC technology's environmental and economic benefits (2020)

Rigorous Testing & Validation

Comprehensive laboratory and industrial-scale trials confirming performance metrics

Industry Recognition

Acknowledged by leading paper manufacturers and research institutions globally

Technical Specifications

Industry-leading performance metrics backed by rigorous testing

Synthesis Efficiency

CNF Yield Ratio

Processing Time

Energy Consumption

Performance Characteristics

Tensile Strength

Opacity Enhancement

Surface Smoothness

Economic Impact

Pulp Replacement

Cost Savings

ROI Timeline

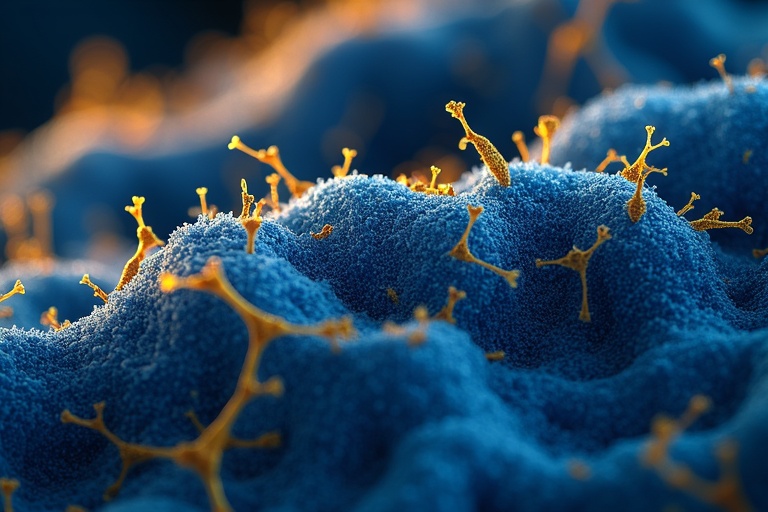

Breakthrough Synthesis Process

Mineral Filler Integration

Advanced binding technology enables unprecedented filler-to-CNF ratios

Optimized Dispersion

Uniform distribution ensures consistent paper quality and performance

Enhanced Bonding

Superior fiber-to-filler adhesion maintains structural integrity

Ready to Transform Your Paper Production?

Join leading manufacturers worldwide who are revolutionizing their operations with FCC Technology.

Exclusive Territory Rights

Secure competitive advantage in your regional market

Technical Support

Comprehensive training and ongoing engineering assistance

Proven ROI

Rapid payback period with substantial cost savings

Our licensing team will respond within 24 hours to discuss customized solutions for your specific manufacturing requirements.